5.3L Engine Rebuild Page 35

Figure 137. Here is the PSC SP1405 P Series Power Steering Pump. This unit has higher pressure and flows more fluid than a stock gm pump. Installation is easy as it will bolt right up to the stock bracket mount. This uni also has AN connections, 6 AN for output, and 10 AN for fluid in.

Figure 138. Three bolts on the bracket bolt the pump right up. For looks, we replaced the factory bolts with black socket head screws with washers.

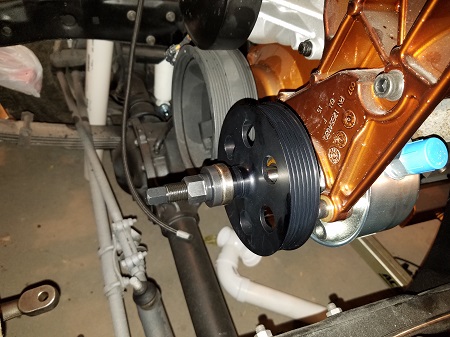

Figure 139. Installing the 5.6 inch pulley, make sure the ribs line up with the ribs on the balancer pulley. This will make the belt run true and not fly off from misalignment.

| Pages: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39 |

| <--Previous | 5.3L Engine Build Home | Next--> |

| Contact: Copperhead | As an Amazon Associate I earn from qualifying purchases | © 2019 |