5.3L Engine Rebuild Page 17

Figure 65. The next step is getting this broken bolt out. This is on the exhaust port. This is a common problem with the LS engine and factory bolts. A left hand drill bit and a screw extractor should get it out, we will see.

Figure 66. The bolt did not come out easily. the screw extractor snapped off. We were forced to take it to a machine shop to get it out. Here, the drivers

side head is installed. The 11mm bolts are torqued to 75ft lbs in three steps. the 8mm bolts are torqued to 25ft lbs in three steps. Be sure to follow

the factory torque sequence. All head botls are ARP 134-3609 Pro Series Head Bolt Kit. The intake ports were taped off after installation to prevent anything getting into the engine.

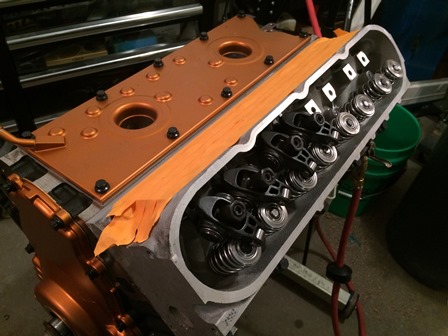

Figure 67. The passenger side head is now installed. The same procedure as used on the drivers side head for the installation.

Figure 68. Once again, the intake ports were taped over to prevent anything getting into the engine prior to intake manifold installation.

| Pages: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38 |

| <--Previous | 5.3L Engine Build Home | Next--> |

| Contact: Copperhead | As an Amazon Associate I earn from qualifying purchases | © 2019 |