5.3L Engine Rebuild Page 34

Figure 133. Installation of the Trick Flow 4-corner steam vent kit was begun. According to the installation instructions, the tee going to the radiator is usually on the drivers side, but with the truck bracket in the way, it will have to be installed on the passenger side. that will be good because the hose can then be run alongside the upper water pump hose and attached to it with cable ties for a cleaner installation. This kit has a hose connection at all four corners which will help to eliminate hot spots in the cooling system.

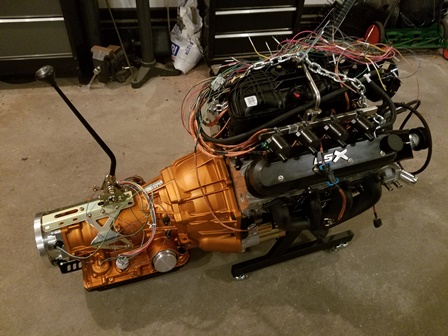

Figure 134. Installed the transmission onto the engine. There are six M10 bolts, torqued to 37ft lbs. The engine was put on Motofeet stands so that the transmission could be attached. These stands also have steel casters. They work, but with the weight, it still is not easy to move around. Mechanically this engine is now complete. The wiring harness necessitated the transmission being put on as individual harnesses for it are also incorporated into the wiring, and it is very difficult to gauge length with the unit not bolted on. Harness completion will be the final step before this is placed into the Jeep.

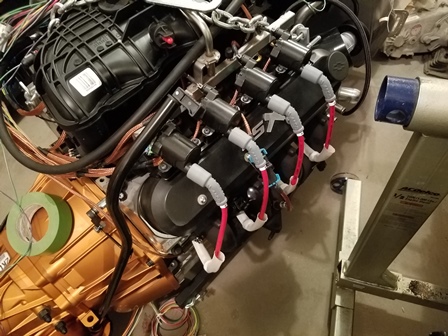

Figure 135. Here are the new spark plug wires installed on the driver side. These are the MSD wires for the 8.1L. They are the perfect length for the coil packs mounted on the ProForm brackets. They also come with a heat shield already installed, very nice!

Figure 136. Here is the new MSD 39849 8.5mm Spark Plug Wire Set on the passenger side. Things are coming together nicely.

| Pages: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39 |

| <--Previous | 5.3L Engine Rebuild Home | Next--> |

| Contact: Copperhead | As an Amazon Associate I earn from qualifying purchases | © 2019 |