5.3L Engine Rebuild Page 32

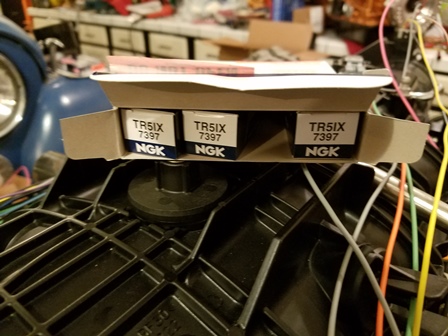

Figure 125. Installed the spark plugs, they are NGK TR51X Iridium spark plugs. They are installed finger tight, to prevent cross threading, then torqued to 13ft lbs. Compression feels good, very difficult to turn the motor over by hand now with the plugs in.

Figure 126. The spark plugs installed. Plenty of room around the manifold for the spark plug wires and boots.

Figure 127. Here you can see the coils and injectors grouped up, along with the map sensor and oxygen sensor. Also, a set of used coils were bought from ebay that were in far better shape than the coils that were on the original engine. They look much nicer and are not so rusty and nasty.

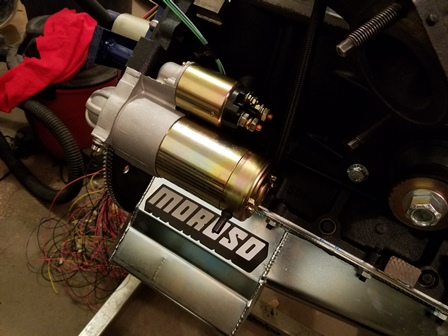

Figure 128. The new starter is installed, it came from DB Electrical, very reasonable price. The bolts are 2 long ARB starter bolts. Torque to 37ft lbs.

| Pages: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39 |

| <--Previous | 5.3L Engine Rebuild Home | Next--> |

| Contact: Copperhead | As an Amazon Associate I earn from qualifying purchases | © 2019 |