4L60E Transmission Rebuild Page 26 of 29

Figure 101. Fill the torque converter with approximately 1-1/2 quarts of transmission fluid. Push it onto the turbine shaft and pump splines. Rotate it slightly as you push it in, and engage the pump drive tangs. It will be below the outer edge of the bellhousing when it is on all the way.

Figure 102. this shows how far back the torque converter should be when it is in all the way.

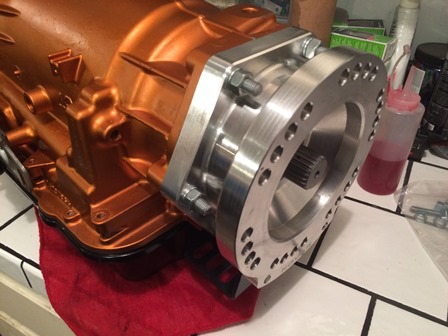

Figure 103. Use Blue 243 Loctite and install the studs hand tight in the rear of the transmission case. Install the square cut seal on the Novak transfer case adapter. Lubricate the ring and transmisison bore with transmission fluid prior to final installation.

Figure 104. Install the adapter and the lockwashers and nuts and tighten them down in a star pattern.

| Pages: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29 |

| <--Previous | 4L60E Rebuild Home | Next--> |

| Contact: Copperhead | As an Amazon Associate I earn from qualifying purchases | © 2019 |