5.3L Engine Rebuild Page 31

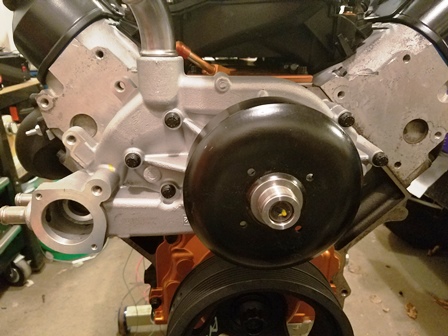

Figure 121. Installed the water pump, also using ARP bolts. This pump came with the o-ring style gaskets, so no sealant was necessary, since the block surface is new and has no residual gasket or sealant on it. The bolts are torqued in a criss-cross pattern in two stages. The first stage is 11 ft lbs, and the second stage is 22 ft lbs.

Figure 122. Installed the thermostat and housing. ARP 12-point bolts were used for this. They are torqued to 11 ft lbs.

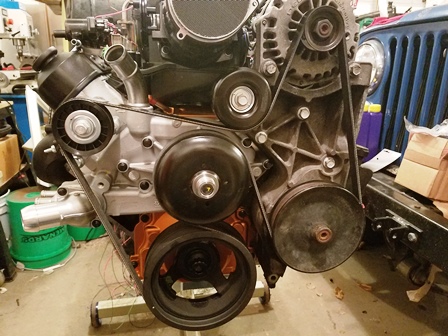

Figure 123. All the belt drive accessories are installed. The power steering pump, bracket, and alternator are on here temporarily until they can be replaced/cleaned up. For now, they are installed to get wiring positions set and to make sure the belt will line up properly.

Figure 124. Installed the belt to make sure that everything is aligned and set the way it is supposed to be. The belt is a Dayco 5060930 Poly Rib belt. This is the belt for the 130 amp alternator. The belt for the 105 amp alternator is too short for this set up, as was found out the hard way. There were no identification markings on this alternator, so we guessed it at 105 amps at first, which was incorrect.

| Pages: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39 |

| <--Previous | 5.3L Engine Rebuild Home | Next--> |

| Contact: Copperhead | As an Amazon Associate I earn from qualifying purchases | © 2019 |