5.3L Engine Rebuild Page 14

Figure 53. Buying a cheap aftermarket timing cover was a mistake. This is a Pioneer unit. Apparantly they use the same casting for Gen III and Gen IV timing covers, as this one has the boss in it for the Gen IV cam sensor, but the hole is not drilled. The original factory cover for the Gen III does not have this boss. The double timing chain hits on this boss, and it must be removed for the cover to fit properly. This will be removed with a milling machine. It could also be cut out with a die grinder.

Figure 54. The Morel 5315 lifters, to be installed in the block. These are supposed to be one of the best non-tie bar lifter available, second only to the Johnson lifter, at the time of this writing in 2016.

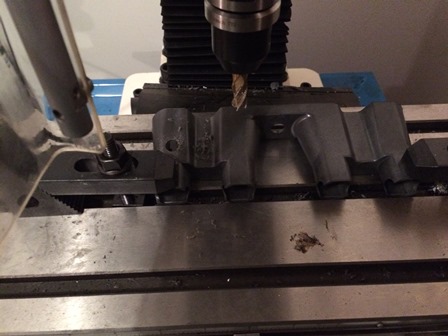

Figure 55. To aid in oil recovery, drainback holes are being drilled in the 12595365 Roller Lifter Guides. Without these, oil pools to the top of the tray and

spills over. A milling machine was used here, with a 3/8 bit, but a drill press or hand drill can do the job also.

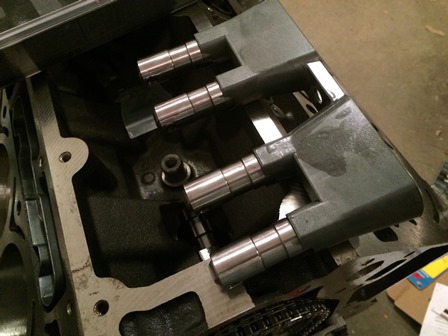

Figure 56. The lifters are lubricated with engine oil then placed in the trays for insertion into the block.

| Pages: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38 |

| <--Previous | 5.3L Engine Build Home | Next--> |

| Contact: Copperhead | As an Amazon Associate I earn from qualifying purchases | © 2019 |