4L60E Transmission Rebuild Page 14 of 29

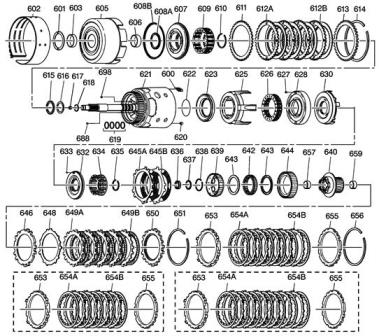

Figure 53. This diagram is from the GM parts manual. It shows how the clutches and input drum go together. We have already installed the pistons, now soak your clutches in transmission fluid before installing them in the drum. Install the overrun clutch first, steel, friction, steel friction, ending with the forward clutch apply plate. Install the forward sprag assembly. Install the forward clutch wavy steel. then install the first forward clutch steel. Alternate steels and frictions, ending with the forward clutch pressure plate. Install the snap ring in the drum.

The next part is where things get tricky with the Smart Tech Input drum. We need to make sure our clearance on the 3-4 clutch pack is at least .054 minimum when using Raybestos Blue Plate .062 thickness frictions. The only way to adjust the clearance on the 3-4 clutch pack is with steels and frictions of differing thicknesses. To acheive my clearance at .060, I used .078 and .082 kolene steels and 8 .062 Blue Plate frictions. It took a bit of swapping to get it right, as the steels vary in thickness slightly, even though they say they are .078 and .082 respectively, some of them measure a few thousands more. Use a feeler gauge between the top friction and the pressure plate ring to measure your clearance. When clearance is set, torque the screws on the ring to 50 inch pounds.

Figure 54. The final part of the input drum assembly is the teflon shaft seal rings. The GM tool for this is very very expensive. A tool was bought on Ebay to do this, and after arrival, it was determined that if you are very very careful, you do not really need it at all. Carefully expand the rings with a seal pick on the shaft, and you can open them up just enough to get them on without damage.

Figure 55. The ring resizer that came with the tool is nice though. You can accomplish the same thing by wrapping them tightly with electrical tape, sticky side out.

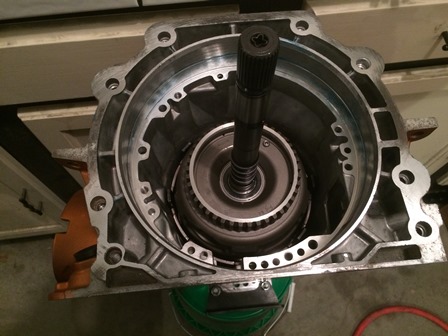

Figure 56. Install the splined seal in the end of the inner shaft of the input drum.Dunk the torrington bearing that goes over the end of the inner shaft, and place it in the input drum. Place the input drum over the front planetary in the transmission, Make sure it is all the way down.

In the next step, we will be installing the reverse input drum and checking end play of the input shaft. There are shims and a torrington bearing on top of the input drum that set the end play once the pump is installed.

| Pages: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29 |

| <--Previous | 4L60E Rebuild Home | Next--> |

| Contact: Copperhead | As an Amazon Associate I earn from qualifying purchases | © 2019 |