CJ7 Build Page 31

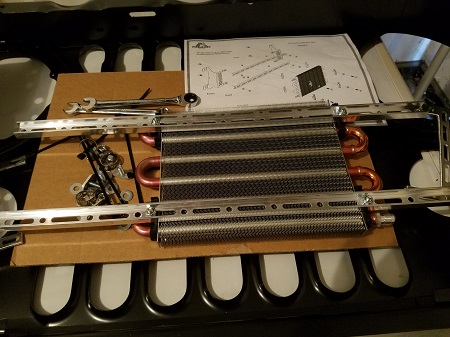

Figure 119. Here the cooler is now attached to the C-Channel brackets. The nuts are a tight squeeze to get a wrench or socket on. We used a screwdriver as a wedge to keep the nylock nuts from turning as the bolts were tightened.

Figure 120. The cooler is now assembled and set in the grill, it cannot be bolted in until the radiator goes in, the brackets for both use the same bolt holes.

Figure 121. Here is the Flexalite 51168LS radiator with fan for the CJ7. This item is no longer available, but Flexalite has a new version of it with their extruded radiator core, it is Flex-a-lite 315861 Extruded Core Radiator for LS Engine. The inlet and outlet are both on the passenger side.

Figure 122. The captive nut that came with the kit was too long. We do not know if they put the wrong ones it, or if the kit was mis-packaged or what.

| Pages: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, |

| 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35 |