CJ7 Build Page 30

Figure 115. A view of the rear section of fuel lines protected with the 1/2 inch split loom.

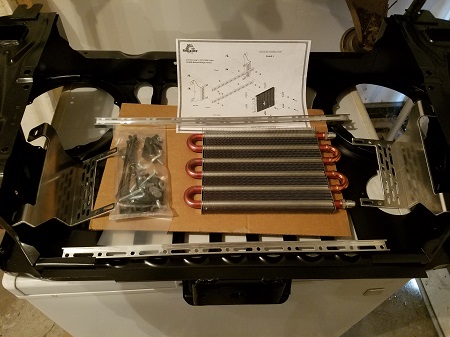

Figure 116. Now that the fuel lines are ran, we move to the cooling system. We start with the Flex-a-lite 41166CJ Direct-fit Transmission Oil Cooler with 6AN Fittings which goes into the grill first. Shown are all the items that come in the kit. All brackets and hardware is included.

Figure 117. These are the gator clips that go on the cooler tubes to attach it to the mounting brackets. There are 4 of these in each kit.

Figure 118. Here we see the gator clips mounted on the tubes of the cooler. The bolts go through both clips and into the brackets.

| Pages: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, |

| 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35 |