CJ7 Build Page 25

Figure 95. The crossmember is now finish welded, and painted, ready to install. It was painted with Eastwood Rust Encapsulator as the base coat, then Extreme Chassis Black Satin as the top coat.

Figure 96. The crossmember is now installed. With the transfer case clocked flat, there was a clearance problem between the case and the crossmember, the case was resting on the crossmember on the passenger side. This will have to be corrected, as there needs to be room for movement of drivetrain assembly.

Figure 97. The solution was to add extra thick washers as spacers between the transmission mount and the crossmember plate. The original mount used one bolt, (It had provision for three.) Holes were drilled in the mount plate for the two outer bolts. Two extra-thick washers per bolt were installed between the plate and mount, raising it up approximately 3/8 of an inch.

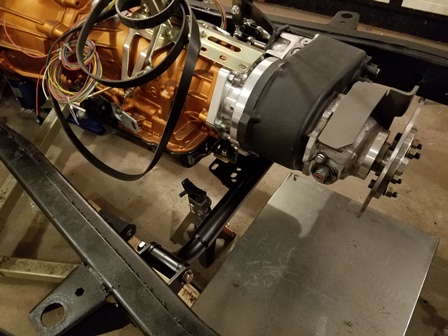

Figure 98. You can see in the photo that we now have approximately 1/4 inch of clearance for the transfer case, which gives plenty of room for movement with no danger of crashing into the crossmember. The front yoke is a 1310. We wanted a 1350, but it will not clear the transmission.

| Pages: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28 |